Need for Automation in Manufacturing: Looking Ahead of Time

To keep up with the continuous need to generate higher throughput and reduce costs,

manufacturing organizations are integrating automation and Industry 4.0 solutions to

improve their efficiency.

In this post, we will delve into the reasons why manufacturers need automation, types of

automation, how automation deals with the underlying issues, and the future outcome of

human-machine interaction.

Why Automation is the Need-of-the-Hour?

In the context of manufacturing, automating systems or production processes is about

moving away from manual interventions. Overall, the end goal is to increase production

capacity, drive greater efficiency, and reduce costs.

Here are the main reasons for automation:

Increased labor costs

The spikes in labor costs have been a major concern for global manufacturing enterprises, which increase the total operating costs. This is why increased investment in automation has become an economically viable option to replace manual operations. According to the US News, automation in the manufacturing units is likely to lower labor costs by 16 percent on average across the world.

Hazardous working conditions leading to increased accidents

The safety and physical well-being of workers has become a top priority for governments across the world, which led to the enactment of new labor laws. By automating specific processes and realigning the workers from dangerous or accident-prone tasks to other roles, an organization can make working conditions safer.

Companies are less adaptive to change and need to be more competitive

The main objective of manufacturers should be getting the long-term value from automation. Process automation will enable companies to reduce cycle times, improve quality, and reduce and cost-per-piece. However, many companies are still not ready to embrace change and fall short of having a competitive edge. By identifying the areas and applying automation, they can substantially increase their profitability.

Labor Shortage

In the countries where companies face the brunt of labor shortage, automation can play a crucial role as a substitute for human resources. According to IndustryWeek, to keep pace with an on-demand economy, globally 87 percent of companies are currently in the planning phase to expand the size of their warehouses by 2024. It would be possible through automation only.

Human workers undergo exhaustion due to working countless hours

The adverse effects of long working hours on employees are high workload, fatigue, and exhaustion. Automation can streamline processes and reduce human workloads. Studies have revealed that voluntary implementation of automation is likely to improve workers’ alertness and ability to manage fatigue.

Lack of consistency and reproducibility due to human errors leading to reduced part quality

Manual manufacturing processes are routine, boring, and potentially cause more errors. Automating those tasks can significantly improve consistency, minimize errors, and increase part quality.

Increased outsourced costs and lead times & increased dependency on vendors

In the case of outsourced activities, there are often higher lead times, increased costs, and reliance on vendors. It is possible to do away with all of these by automating processes and minimizing the elapsed time between an order and product delivery. By reducing lead times, manufacturers can also lower work-in-process inventory.

Efficiency reduction

In the case of some processes, it is not possible to accomplish goals without the help of a machine. Those complex processes require precision, miniaturization, and quality, which are not feasible to achieve manually. Integration of automation is necessary for such areas for better efficiency and high throughput.

Versatility

Automation is not just efficient, it is versatile too. Automation enables an organization to grow within its current facility through optimum utilization of resources and space. It provides flexibility to relocate and realign equipment to achieve diversity in production.

Types of Manufacturing Automation

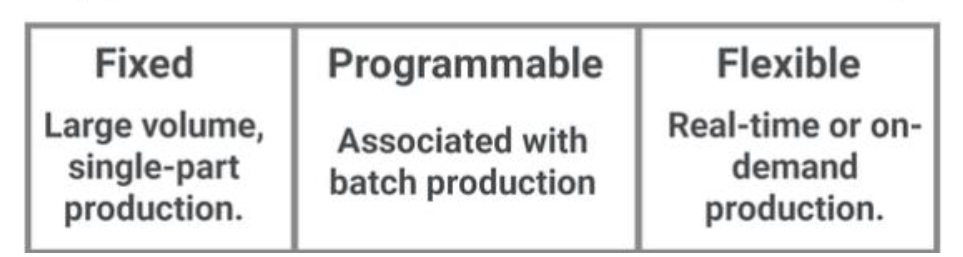

Most manufacturing enterprises find benefits in one of these types of automation below:

▪ Fixed Automation: Used for single-part and large volume production. Example: An

assembly line dedicated to wet cast production.

▪ Programmable Automation: Used for batch production with reconfiguration. Example:

Batch production of mold.

▪ Flexible Automation: Used for on-demand production. Example: Production of different

part types with various lifecycles without manual changeovers.

Human-Machine Interaction: An Ideal Approach

Although it seems tempting for manufacturers to think of automation mainly as a way to save

labor, it has broader benefits than only lowering labor costs. It is crucial to integrate

automation in the settings where there will be interactions between humans and machines to

improve overall performance.

A good example is GCI Group’s Automated Precast System (APS) to increase the wetcast

production efficiency for precast concrete products. Generally, wetcast production faces

challenges, such as wasted motions, process inefficiency, overhead lifting of concrete above

employees, and space limitations. By implementing APS, an organization can increase

throughput, resolve labor issues, improve plant condition, increase profitability, and position

itself as a market leader